What if you could have a zirconia restoration that's as strong as steel and as natural as porcelain?

With dental ceramics in today's era needing to be both fracture-resistant and picture-perfect, knowing which zirconia block to select can make or break a case.

Why the Zirconia Choice Matters

The worldwide market for zirconia-based restoratives in the dental industry is expected to expand at an 8% CAGR from 2025 to 2030, demonstrating how clinicians want materials that provide both longevity and natural looks.

The correct block selection will provide long-term success, evading catastrophic chipping or an overly opaque outcome that will leave patients dissatisfied.

Overview of the Translucency vs. Strength Trade-Off

Zirconia composites vary from high-translucency 5 mol% yttria (5Y) blocks, suitable for anterior crowns, to ultra-tough 3 mol% yttria (3Y) monolithic discs intended for bruxers and long-span bridges.

Each option is a compromise between light transmission and flexural strength, and it is essential to recognize when to prioritize one over the other to attain both functional survival and smooth smile integration.

The Fundamentals of Zirconia

Before you grab that next block of zirconia, consider having a crystal-clear understanding of how its internal grain structure makes or breaks your restoration's performance.

Crystal Phases & Mechanical Properties

3Y-TZP (Tetragonal-Rich)

- Primarily tetragonal grains (> 95 %) for outstanding fracture toughness

- Perfect for high-load regions and long-span restorations

4Y/5Y-TZP (Cubic-Enhanced)

- High cubic phase (up to ~50 %) for optimum light transmission

- Balances strength and aesthetics for anterior and posterior single units

E-Max Layered Zirconia

- Zirconia core veneered with lithium-disilicate porcelain

- Blends core strength with vivid, enamel-like translucency

Translucency & Clinical Relevance

Light Transmission

- More cubic content → greater lifelike brilliance

- Essential to simulate the depth and fluorescence of natural enamel

Flexural Strength

- 3Y-TZP blocks resist heavy occlusal forces with minimal chipping

- 4Y/5Y blocks maintain sufficient toughness for single crowns and short-span bridges

Aesthetic vs. Stress Zones

- High-translucency blocks for smile-zone restorations

- High-strength blocks for bruxers, posterior bridges, and implant frameworks

General Indications by Block Type

Monolithic 3Y-TZP

- Posterior crowns, long-span bridges, and heavy-grinding patients

Multilayer 4Y/5Y-TZP

- Single crowns, veneers, and aesthetic implant abutments

E-Max Layered Zirconia

- Ultra-thin veneers (< 0.5 mm) and challenging anterior aesthetic cases

Quick Comparison Table

| Block Type | Dominant Phase | Key Property | Typical Indications |

| 3Y-TZP Monolithic |

Tetragonal (~95 %) |

Maximum fracture toughness | Posterior units, long-span bridges, bruxers |

| 4Y/5Y-TZP Multilayer | Cubic (25–50 %) | Enhanced translucency | Single crowns, veneers, and anterior implants |

| EMax Layered | Zirconia + Porcelain | Porcelain-like esthetics | Ultra-thin veneers, high-demand anterior restorations |

Comparing Translucent (4Y/5Y) vs. High-Strength (3Y) Zirconia

Imagine knowing in an instant if your next case requires the maximum resilience of 3Y or the natural sparkle of 5Y, with no guesswork. This head-to-head analysis makes the decision crystal clear.

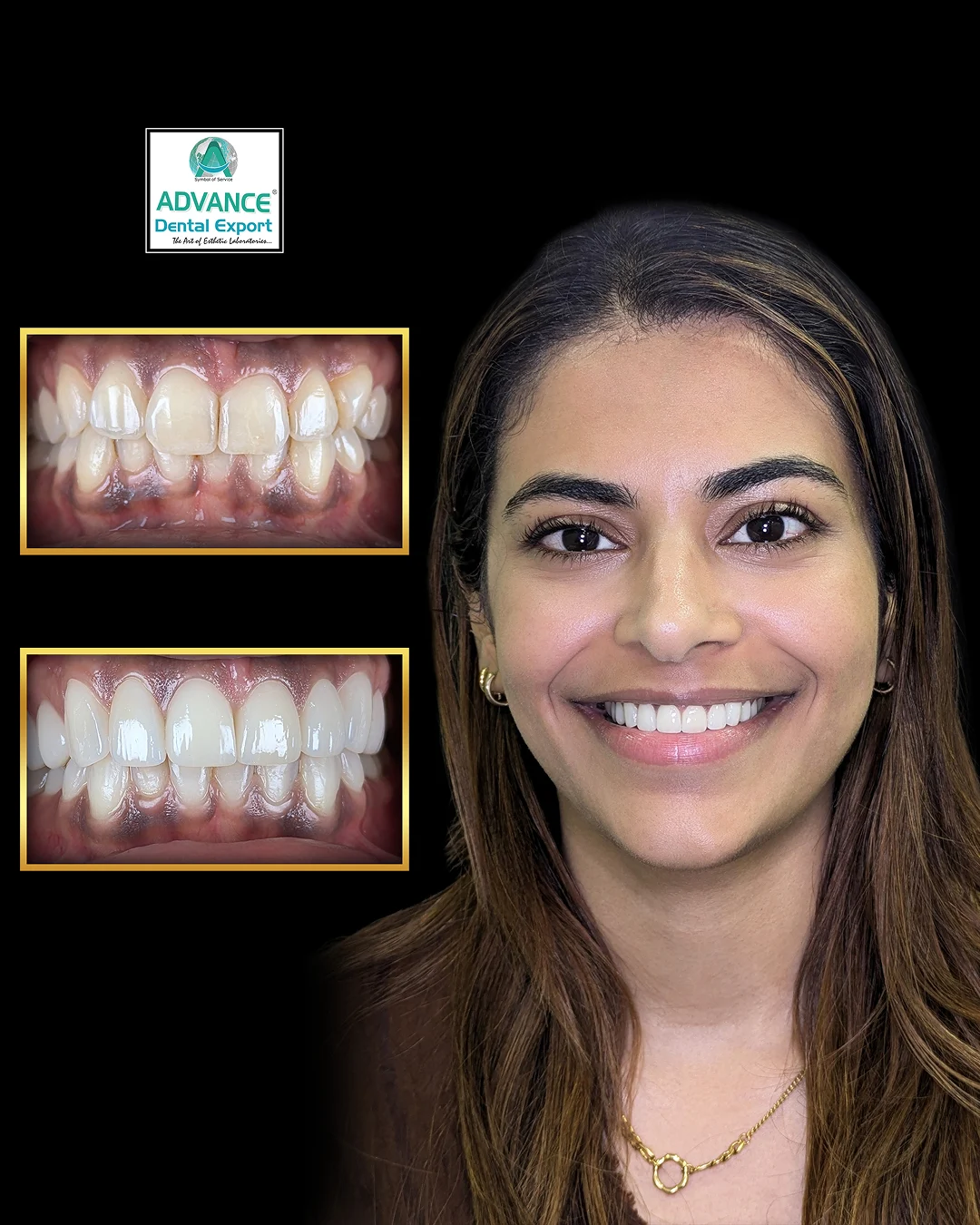

Explore Our Restorations

Flexural Strength & Fracture Resistance

3Y-TZP Blocks

- Flexural strength: 1,100–1,250 MPa

- Ideal for multi-unit bridges, implant frameworks, and bruxers

4Y/5Y-TZP Blocks

- Flexural strength: 650–850 MPa

- Ideal for single units and short-span bridges where moderate loads are exerted

Optical Properties & Shade Matching

Light Diffusion

- 4Y/5Y Zirconia: Scatters light with high cubic content for a natural enamel radiance

- 3Y Zirconia: Tighter grain structure offers opacity to cover up dark stumps

Shade Consistency

- 4Y/5Y usually combined with external stains for increased chroma

- 3Y depends on intrinsic shade formulas for even value

Minimum Thickness & Preparation Requirements

| Property | 3Y-TZP High-Strength | 4Y/5Y-TZP Translucent |

| Recommended Wall Thickness | 0.7–1.0 mm | 0.6 mm |

| Finish Line | Shoulder or chamfer | Chamfer preferred |

| Stump Masking | Excellent | Moderate (use opaquer) |

Tip: Apply a slightly thicker finish line on 3Y blocks to optimise toughness and precise margin control on 4Y/5Y to maximise translucency.

Processing Protocols: Sintering, Staining & Polishing

Sintering

- 3Y-TZP: Can handle rapid cycles for greater throughput

- 4Y/5Y: Needs slower ramps to maintain cubic phase and translucency

Staining & Characterization

- External stains can merge with 4Y/5Y's gradient

- Infiltration stains are recommended for 3Y to avoid surface chipping

Polishing & Glazing

- Mirror finishes obtained on both using diamond paste and goat-hair brushes

- Glazing on 3Y minimizes surface opacity and the chance of microfractures

Clinical Decision Guide

Picture this: having a built-in "zirconia GPS" that directs each case directly to the ideal block—no shortcuts, no trial and error. Use this guide to navigate your way in seconds.

Case-Based Decision Metrics

| Clinical Scenario | Recommended Block Type | Rationale |

| Single Anterior Crown (A1–A3 shades) | 4Y/5Y-TZP Multilayer | High translucency for lifelike esthetics |

| Thin-Prep Veneer (<0.5 mm) | EMax Layered Zirconia | Ultra-thin strength plus enamel-like translucency |

| Posterior Single Crown, Non-Bruxer | 4Y-TZP (High-Translucency 4Y) | Adequate strength with improved aesthetics |

| Posterior Single Crown, Bruxer | 3Y-TZP Monolithic | Maximum fracture resistance under heavy occlusal loads |

| 3-Unit Posterior Bridge | 3Y-TZP Framework + 4Y Micro-Layer | Core toughness with aesthetic facial layer |

| Full-Arch Implant-Supported Restoration | 3Y-TZP Monolithic | Superior long-span stability and minimal risk of catastrophic fracture |

| Esthetic Implant Abutment (Smile Zone) | 4Y/5Y-TZP Multilayer | Gradient translucency for seamless tissue blend |

| High-Stain Masking Needed (Discolored Stump) | 3Y-TZP with Opaquer | Intrinsic opacity safely masks underlying discoloration |

Introducing The Showstopper: Advance Zirconia

What would happen if one brand were to provide every indication—from bruxer-proof bridges to wafer-thin veneers—without compromise?

Enter Advance Zirconia , your one-stop solution.

Product Portfolio Overview

Monolithic Zirconia (3Y-TZP)

- Flexural strength >1,100 MPa for ultimate load-bearing restorations

- Perfect for posterior crowns, long-span bridges, and implant frameworks

Multilayered Zirconia (4Y/5Y-TZP)

- Graduated translucency simulates natural enamel-to-dentin transitions

- Ideal for single anterior crowns, veneers, and esthetic abutments

Zirconia Implants

- Full-ceramic implant fixtures for metal-free, biocompatible solutions

- Guarantees up to 20–25 years of longevity if properly cared for

E-Max Layered Zirconia

- Blends zirconia core strength with lithium-disilicate porcelain aesthetic

- Recommended for ultra-thin veneers (< 0.5 mm) and high-visibility cases

Key Technical Specifications & Clarification

| Feature | Specification/Benefit |

| Flexural Strength | > 1,100 MPa (3Y) / 650–850 MPa (4Y/5Y) |

| Translucency Gradient | Multilayer discs with built-in shade transition |

| Biocompatibility | Zirconium dioxide—metal-free, hypoallergenic |

| FDA Registration | Manufactured in an FDA-registered facility |

| CAD/CAM Compatibility | Pre-calibrated shrinkage factors for < 40 µm marginal gap |

| Surface Finish | Non-porous, stain-resistant, gum-friendly |

What Makes Advance Zirconia Stand Out

- Unified Portfolio : No more juggling multiple brands—one partner for every zirconia indication.

- Proven Longevity : Clinical cases show minimal chipping or wear after 5+ years in function.

- Natural Aesthetics : Built-in shade and translucency gradients eliminate cutbacks and layering steps.

- Technical Support : End-to-end guidance—from STL submission to sintering protocol—backed by our expert team.

Looking for a trusted lab partner? Get high-precision restorations from Advance Dental Export

By choosing Advance Zirconia, you’re not just picking a block—you’re partnering with a complete zirconia ecosystem designed for predictable, high-quality outcomes.

How to Use Advance Zirconia in Your Workflow

What would it be like if incorporating a new zirconia system became as easy as sending your next case with a click?

Go through these steps to integrate Advance Zirconia into your digital-restoration workflow—no frustration, just reliable outcomes.

CAD/CAM Settings & Shrink-Factor Calibration

- Pre-Calibrated Profiles : Utilize Advance Zirconia's vendor-provided shrink-factor files to obtain < 40 µm marginal gaps

- Machine Compatibility : Compatible with leading CAM platforms (Roland, Amann Girrbach, vhf, Straumann CARES)

- Toolpath Strategies : 5-axis roughing at 1.2 mm step-over; finishing at 0.1 mm for sharp margins

- Mill-Dry Planning : Dry-mill 3Y blocks; wet-mill 4Y/5Y to maintain translucency

Preparation & Sintering Protocols

Tooth Preparation

- 3Y-TZP : Minimum of 0.8 mm occlusal, 0.7 mm axial reduction

- 4Y/5Y-TZP : Minimum of 0.7 mm occlusal, 0.6 mm axial reduction

Sintering Cycles

- 3Y-TZP : Rapid cycle (2 hours total), ramp 80 °C/min to 1,450 °C

- 4Y/5Y-TZP : Slow cycle (3 hours total), ramp 60 °C/min to 1,450 °C

Cooling

- Controlled cool-down (5 °C/min) for 4Y/5Y to preserve cubic grains

Staining & Characterization Tips

- Intrinsic Layers : Take advantage of inherent gradient of multilayer discs—least cutback necessary

- External Stains : Use on fired restoration at 750 °C; fine brushes for natural line angles

- Glaze vs. Sealant : Light glaze on 3Y-TZP; sealant spray adequate for 4Y/5Y to preserve depth

Cementation & Polishing Best Practices

Surface Conditioning

- Sandblast intaglio at 1 bar with 50 µm alumina; clean in ultrasonic bath

- Apply MDP-containing primer for chemical bond

Selection of Cement

- Dual-cure resin cements suggested for both types of blocks

Finishing Touches

- Diamond-impregnated silicone cups → diamond paste → goat-hair brush to polish

- The final glaze layer on 3Y extends longevity; it is optional on 4Y/5Y for natural lustre

Conclusion

Selecting the appropriate zirconia block is never a trade-off between aesthetics and strength— Advance Zirconia provides both within one unified system.

From fracture-resistant monolithic 3Y-TZP for high-stress indications to the natural gradients of multilayer 4Y/5Y-TZP for anterior restorations, our pre-calibrated CAD/CAM profiles and optimized sintering protocols provide predictable fit and amazing results every time.

Ready to experience Advance Zirconia? Book a one-on-one workflow consultation with our technical team at [email protected]

Let's raise your zirconia restorations to the next level.