Under the cool glow of the scanner, a precise digital map of your teeth emerges, every bend, every gap recorded to a fraction of a millimetre. A few minutes later, an exquisitely milled bridge comes out, ready to slide in like a missing piece of a puzzle.

Accurate digital processes convert guesswork to certainty. In long-span dental bridges , where slight inaccuracies can result in a bad fit or breakage, this exact accuracy provides:

- Seamless margins that exclude bacteria

- Even pressure distribution between several teeth

- Massively fewer remakes and adjustments

The Role of Precision in Digital Dentistry

Picture yourself slipping into a suit custom-fitted to every contour, no pinching, no looseness. That's what precision does for long-span bridges: a custom fit that's seamless from the moment it's seated.

What "precision" actually looks like

- Ultra-detailed scans : Intraoral scanners color your teeth with millions of data points, every detail and nuance mapped so nothing gets lost in the cracks.

- Perfect virtual blueprints : CAD software converts those scans into a 3D model you can examine and adjust until it's perfect, down to a single micron.

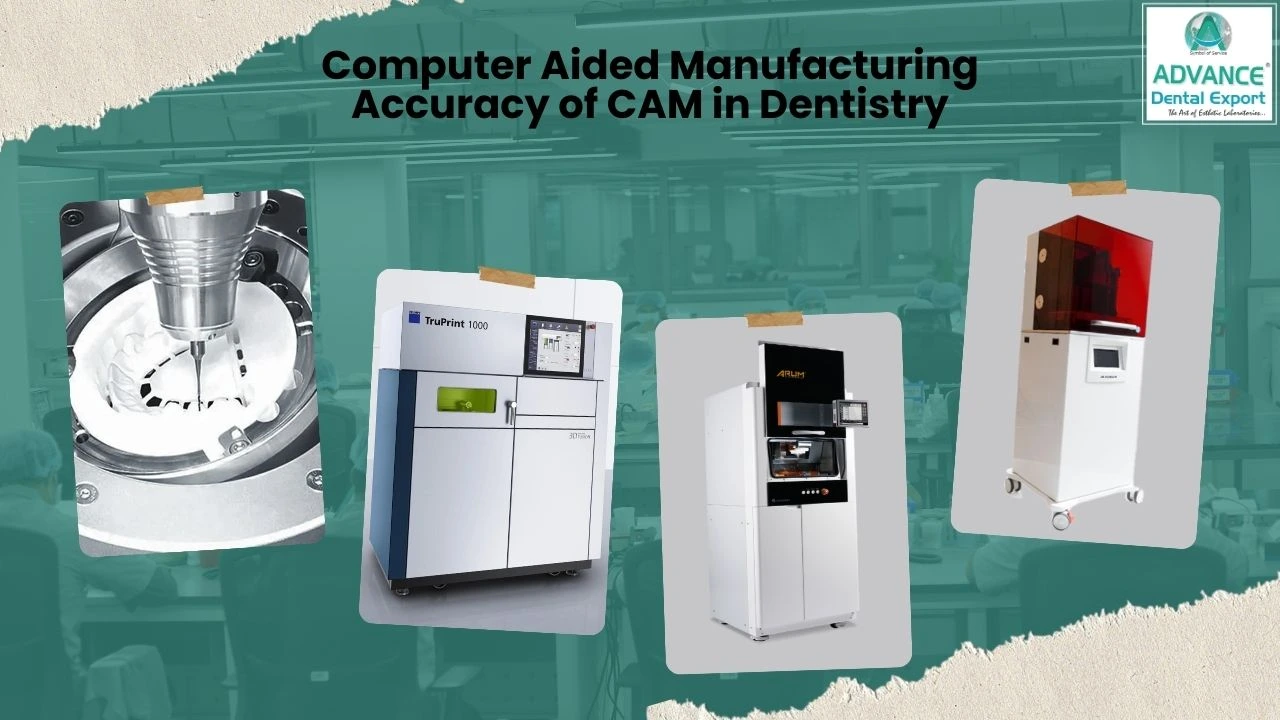

- Perfect milling or printing : CAM machines then replicate that digital blueprint to cut or 3D print the bridge just like it was imagined, no surprises, no recontouring chair-side.

How tiny variations have a giant effect

- No sneaky gaps : Bridges embracing tooth edges provide not an inch of room for sneaky bacteria, keeping your smile healthier below.

- Easy flossing : When the space between contacts is just right, you guide floss or water through without pulling or snagging.

- Even chewing comfort : Proper force distribution across each pontic means biting into an apple or savoring steak without concern for pressure points.

- Quick, hassle-free appointments : A pontic that goes straight off the mill eliminates tedious trial fittings, so you're in and out, and back on with your day.

By working with every step as an accurate, digital handoff, long-span bridges don't seem so much like dental work and more like an organic extension of your smile.

Advantages of Long-Span Dental Bridges

When a smile crosses many teeth, even the slightest misfit can mean trouble or discomfort in the future. Precision digital dentistry processes deliver two key advantages.

Superior Marginal Adaptation

- Bacteria's worst enemy : When the bridge margins fit the tooth snugly, there's no place for plaque or bacteria to hide, margins healthy and avoiding decay along the edges.

- Feels like part of you : That smooth connection results in no poking or snagging against soft tissue. You hardly even know the bridge is there, whether you're drinking soup or smiling.

- Confidence with every bite : With margins that engage and stay put, you chomp into sandwiches or apples without hesitation, confident the fit will remain rock-solid.

Decreased likelihood of Framework distortion

- Consistent material integrity : Computer planning and precision milling avoid the slight warps or twists from hand-fitting frameworks.

- Even load on pontics : A perfectly crafted framework distributes chewing forces evenly, so no single pontic carries additional load, reducing stress fractures.

- Fewer unexpected repairs : Bridges made to precise specifications hardly ever require mid-course corrections, saving you additional appointments and discomfort.

Explore Our Restorations

With each margin and millimeter of the structure carefully designed, long-span bridges are a safe extension of your smile, made to last and feel like nature.

Streamlined Design and Manufacture

Seamless digital process makes designing long-span bridges more like building a custom work of art, each step aligning perfectly without resistance.

Digital Scanning and CAD Planning

- Immediate, accurate impressions : Intraoral scanning takes seconds to capture your mouth, trading slimy putty for a quick digital impression .

- Hands on Virtual Sculpting : Your lab technician and dentist can refine contours and contacts on screen, rotating, zooming and tweaking until it feels perfect.

- Real-time feedback : Identify potential trouble areas (such as tight undercuts or high bite points) before anything is milled, so surprises never arise later.

Consistent Milling and 3D Printing

- Factory-like accuracy : Milling machines adhere strictly to the digital blueprints, machining every pontic and connector with mechanical precision.

- Repeatable results : Whether it's your one and only bridge or your fifth, the same file creates the same fit, no more ticks and quirks from hand work.

- Speed without compromis e: On-site milling or quick-track lab printing has you transition from scan to fitting much more quickly, without compromising on quality.

By integrating these digital dental tools , long-span bridges become sturdy, comfortable restorations, ready to step right into place and remain there for years.

Improved Patient Experience and Comfort

No more endless visits or cringeworthy fittings, precision digital processes place your comfort at the forefront.

Fewer Try-Ins and Adjustments

- Ideal first fit : A bridge made to precise specifications slides in almost as if it belonged there all along, no painful drilling to grind away high areas.

- No gagging on impressions : Digital scans eliminate the cumbersome tray, so no gagging feeling or nasty aftertaste.

- Less stress at the chair : With fewer "try it on, make an adjustment, try it again" cycles, you relax more and stress less about your next appointment.

Reduced Chair Time

- Efficient appointments : From scan to implant, the entire process can be done in one visit, so you're out before lunch.

- Instant feedback loops : Your dentist gets to see the digital model in real-time, identify any issues on screen, and adjust on the fly, no sitting around waiting for lab results.

- Comfortable recovery : Because minimal adjustments are needed, you’re less likely to experience soreness or sensitivity afterward.

A comfort-first approach means long-span bridges feel like a natural part of your routine, not a dental ordeal.

Increased Longevity and Function

Bridges made to digital accuracy aren't simply a matter of having an exact fit, they're designed to last, withstanding daily stress without flinching.

Consistent Stress Distribution

- Equal load on all pontics : Small fit differences can concentrate force onto a portion of the bridge, creating cracks. A framework designed by a computer distributes chewing pressure evenly so that no part of the structure carries the load.

- Lower risk of fatigue fractures : Consistent thickness and precise connector size prevent metal or ceramic from wearing out with repeated bites.

- Consistent Support for Surrounding Teeth : As the bridge functions in coordination with adjacent teeth, you prevent shifting or tilting, which compromises your bite over time.

Consistent Material Properties

- Controlled Sintering Procedures : Zirconia and other high-tech ceramics are heat-treated in calibrated furnaces so that each unit has uniform density and strength.

- Fewer variables, more consistency : In contrast to hand-mixed materials, computer-made restorations work with pre-formulated blocks, so each bridge has the same well-documented performance characteristics.

- Durable that you can depend on : With accurate control over materials, long-span bridges routinely surpass conventional methods by years, leaving you confident that your investment stands up to the demands of life.

Looking for a trusted lab partner? Get high-precision restorations from Advance Dental Export

With careful design combined with reliable, high-quality materials, these bridges provide durability and performance you can trust, bite after bite, year after year.

Collaboration and Communication Benefits

When everyone's on the same page, your dentist, dental laboratory , and you, the outcome feels seamless and hassle-free.

Seamless Lab–Clinician Interface

- Instant case sharing : Digital scans and design files can be uploaded in seconds, so your dentist and the lab work from the same data, no lost impressions or misaligned notes.

- Clear visual feedback : 3D renderings allow both teams to identify potential adjustments before anything is milled, eliminating surprise adjustments later.

- Streamlined approvals : With online portals, you can evaluate and approve designs submitted from home, no additional chair time to simply sign off.

Real-Time Case Monitoring

- Track progress online : Observe when your bridge goes from design to milling to completion, so you have a clear idea of when your appointment is booked.

- Instant issue flagging : If a model indicates a close undercut or connector that's too narrow, the tech marks it in the system, and the dentist can correct on the spot.

- Quicker turnaround : Loops of communication that used to take days now occur in hours, so your final restoration shows up faster and with fewer glitches.

By threading digital communication throughout each step, long-span bridges don't feel as much like a back-and-forth effort and more like one cohesive effort, giving you a precise fit and a comfortable experience you can rely on.

Future Directions in Digital Bridge Dentistry

The digital frontier continues to grow, new technologies vow to make long-span bridges even more accurate, quicker, and more patient-friendly.

AI-Powered Design Improvements

- Intelligent margin detection : Machine-learning algorithms identify and polish important edges in seconds, reducing manual clean-up time.

- Predictive stress modeling : AI predicts where bridges could potentially experience the most chewing forces, allowing designs to be strengthened before fabrication.

- Automatic adjustments : Next-generation software recommends optimal connector size and pontic form based on massive libraries of previous cases, hours of trial and error avoided.

Smooth Scanner-Mill Integration

- One-click processes : Intraoral scanners that directly feed into milling centers cut out file transfers, so designs go directly from capture to production.

- Live milling previews : Live milling dashboards display progress and alert any deviations as they occur, allowing technicians to intervene immediately.

- Cloud-based collaboration : Scans, design files, and milling parameters are synchronized in the cloud, so labs, specialists, and clinicians all collaborate on the same minute-by-minute information.

These advancements in dentistry are not hype; they're revolutionizing how long-span bridges are designed and delivered, taking both fit and patient comfort to new levels.

Take The Final Step

Accuracy digital workflows transform intricate long-span bridges into smooth extensions of your smile, fitting, longer-lasting, and feeling entirely natural.

Ready to harness the strength of pinpoint accuracy for your dental bridge?

Submit your digital impression and contact us today , and look toward a future where every bite and every smile is easy.